ACU-THIK™ is an automated thickness measurement tool incorporating dual contact probes for high accuracy inspection of semiconductor wafers. ACU-THIK™ can be configured to accommodate wafer diameters of 100mm – 400mm and beyond. ACU-THIK™’s patent pending design can help diagnose and control the following:

ACU-THIK™ is an automated thickness measurement tool incorporating dual contact probes for high accuracy inspection of semiconductor wafers. ACU-THIK™ can be configured to accommodate wafer diameters of 100mm – 400mm and beyond. ACU-THIK™’s patent pending design can help diagnose and control the following:• Thickness: The distance through a wafer between corresponding X/Y points on a front and back surface. Thickness is calculated to resolution and repeatability of .00025mm/.00001” (ten millionths of an inch).

• Bow: The deviation of the center point of the median surface of a free, unclamped wafer from the median surface reference plane established by three or more points at equidistant locations on the wafer.

• Warp: The differences between the maximum and minimum distances of the median surface of a free, unclamped wafer from a reference plane. By examining the entire wafer and by virtue of incorporating more comprehensive data points, warp is a more useful measurement of true wafer shape.

• Validation of System, Pre and Post Measurement: ACU-THIK™ calculates the thickness of a certified gage block, prior to the inspection of the wafer and after the conclusion of the wafer inspection routine. This validation ensures the integrity of the data collection for each wafer inspection.

The X/Y location for each thickness data point will be automatically output to MS Excel for further analysis. Programming software runs on Windows 10 and comes complete as a turnkey system. ACU-THIK™ can obtain X/Y/Thickness data points at a rate of 15 points/minute, allowing for greater throughput and more accurate thickness/flatness definition of wafers.

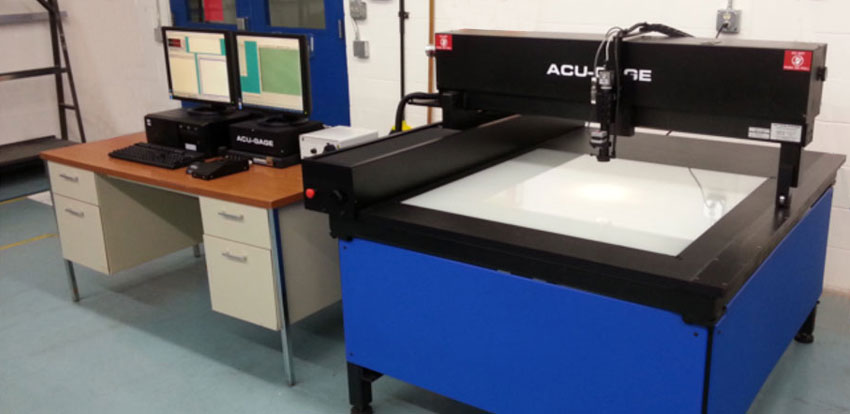

Acu-Gage Systems has announced that Daktronics Inc. (DAKT) has installed a fully automated 36” x 36” Acu-Gage System at its corporate manufacturing operation in Brookings, SD. The Acu-Gage is configured with automated edge detection, full 2-Axis motion control, programmable illumination, and Windows based programming software. Daktronics’ Acu-Gage will supplement a 3-Axis touch probe CMM (coordinate measuring machine) in the quality lab, and provide improved capability and throughput in the measurement of circuit boards, LED assemblies, and flat sheet metal components.

“The addition of the Acu-Gage in the QA lab has provided a significant improvement in measurement time, capability, and programming ease for two-dimensional component measurements,” said Joseph Wiley, Daktronics QA Lab Lead. “Recently, it has been used for thru-hole alignment verification on circuit boards, first article measurements for DVN mod sheets, and verifying manufacturing equipment test parts.”

Jack Kane, Acu-Gage Systems President, said, “We are very excited and pleased to announce the addition of the Acu-Gage System to the Daktronics quality program. Daktronics is clearly the leader in computer programmable displays, and we are honored to be partnering with them to help their continued success. Acu-Gage’s design made it the ideal solution for the large format requirements of Daktronics. Acu-Gage affords increased throughput and accuracy over their previous two-dimensional measuring machine, and I am certain that the Acu-Gage System will be very productive asset for the Daktronics quality program for many years to come.”

Daktronics has strong leadership positions in, and is the world’s largest supplier of, computer-programmable displays, large screen video displays, digital billboards, electronic scoreboards and control systems. The company excels in the control of large display systems, including those that require integration of multiple complex displays showing real-time information, graphics, animation and video. Daktronics designs, manufactures, markets and services display systems for customers around the world, in sport, business and transportation applications.

For more information, click here visit the Daktronics Website.

The Acu-Gage single-axis linear model is a versatile measuring tool used in many diverse industries.

Diecutting applications include the corrugated box, steel rule die and sheet label industries.

Tier 1 automotive suppliers use Acu-Gage to verify cut length of extruded rubber molding for car doors and windows.

Medical companies use Acu-Gage to verify components used in neurological testing.

Credit card companies use Acu-Gage to verify spacing of magnetic stripes on card sheets.

Our customers are always coming up with new and creative applications for Acu-Gage.

Acu-Gage Systems has announced that Enigma Interconnect has installed an automated 24” x 24” Acu-Gage System at its corporate manufacturing operation in Burnaby, BC. The Acu-Gage is configured with automated edge detection, full 3-Axis motion control, programmable illumination, AutoFocus, programmable zoom, and Windows based programming software. Enigma’s Acu-Gage will provide improved capability and throughput in providing first article inspection and process control data for a variety of industry applications.

John Parsons, engineering manager for Enigma Interconnect says, “The addition of the Acu-Gage automated CMM is a necessity that allows Enigma to provide our more demanding customers with the level of FAI reporting they require. The Acu-Gage allows us to take measurements and validate them against applicable tolerances much quicker than could be accomplished by hand. In some cases, these measurements are impossible for us to make using conventional hand measuring tools. We expect the Acu-Gage to be invaluable as a process set-up and monitoring tool.”

Jack Kane, Acu-Gage Systems president, said, “We are very excited and pleased to announce the addition of the Acu-Gage System to the Enigma quality program. Enigma is clearly a leader in the Canadian circuit board market, and we are honored to be partnering with them to foster their continued success. In fact, we share some common clients in the aerospace industry, and I am certain that the Acu-Gage System will be very productive asset for the Enigma team for many years to come.”

About Enigma Interconnect

Enigma Interconnect is one of the premier Canadian PCB manufacturers. Founded in 1973, Enigma Interconnect is a market leader in low- to medium-volume, high-mix PCB manufacturing with exceptional quick-turn services.

Enigma’s diverse customer base covers various high-end manufacturing segments including aerospace, alternative energy, automotive, communications and wireless RF, government and military, medical, and instrumentation. With a production capacity of 500 panels/day and a 35,000 square foot manufacturing facility, the company is a leading circuit board producer in the Pacific Northwest region. Enigma provides climate-controlled areas for all dry film and solder mask operations.

For more information on Enigma, visit www.enigmacorp.com.

Our manual 2-Axis Acu-Gage is a bridge-style CMM. The measuring platform is stationary and the optics move independently above the inspected part. Our modular design allows customers to upgrade their manual Acu-Gage to a fully automated machine over time, an opportunity to grow the capability of the Acu-Gage as business needs change.

Customer applications for the large format 2-Axis Acu-Gage are lithographic printing plates, label manufacturers, gaskets, metal stampings, and printed circuit boards. The Acu-Gage II manual model is an ideal measuring tool for first article layouts and random inspections.